Maersk Supply Service was awarded a contract by an American oil major to deliver an integrated FPSO mooring installation and replacement solution in the Gulf of Guinea.

The project was for the disconnection of a temporary FPSO mooring system and installation of the permanent replacement mooring system. Maersk Supply Service’s full-scope delivery included project management, planning, engineering, design, procurement and marine execution. It also entailed the transport of mooring chains and connectors from China, as well as Intermoor SEPLA anchors and follower from Louisiana.

Project Details

CLIENT

American oil major

PROJECT TYPE

FPSO mooring installation & replacement

PROJECT LOCATION

Gulf of Guinea

NO OF VESSELS USED

4

PROJECT DURATION

April – December 2019

OPERATIONS

Mooring equipment transportation

Temporary moorings disconnection

Permanent moorings installation

SAFETY PERFORMANCE

Zero incidents

Advanced capabilities to accommodate heavy moorings equipment

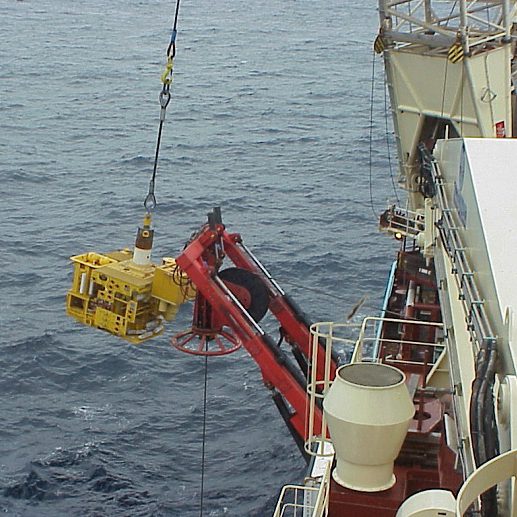

Maersk Maker, a 2019 new-build AHTS vessel, transported and installed nine 25 tonne SEPLA anchors using a 120 tonne follower of 4.3m diameter. The anchors were installed to 27m below seabed, while Maersk Achiever concurrently deployed 650m-long studless chains of 157mm diameter. With some of the most advanced capabilities in the industry, our AHTS and SSV vessels are designed to handle the large mooring systems of tomorrow.

Increased efficiency from two vessels working in tandem

By working with Maersk Maker and Maersk Achiever in tandem, we were able to save time and reduce the number of port calls required. Together, the vessels carried and installed five SEPLA anchors and chain sets per mobilisation, as well as five sheathed spiral strand wires and chains. Tandem operations also prevented entanglement of the large chains and follower during installation in deep waters.

Flexibility in operations from applying 50 years of marine experience

We approach every project from a background of over 50 years of hands-on offshore experience. As it was the first time the mooring equipment was installed at this large size, the on- and offshore project team was able to address the associated challenges, and ensure installation was completed safely and efficiently.