Maersk Supply Service, a partner in the Maersk Decom joint venture, project managed and executed the full scope of decommissioning for the Leadon field in the UK North Sea.

By supplying and managing the entire marine requirement, Maersk Supply Service can

increase flexibility, optimise schedules and reduce risk throughout the project. The

offshore work scope involved cutting the field’s pipe bundles, as well as recovering the

mid-line structure and towheads. With more than 50 years of hands-on offshore

experience, Maersk Supply Service can react safely to unpredictable environments and

unforeseen events which can occur during decommissioning. With this capability,

Maersk Supply Service ensures a safe and efficient project delivery.

Project Details

CLIENT

Total E&P UK

PROJECT TYPE

Decommissioning

PROJECT LOCATION

Leadon field, UK North Sea

PROJECT DURATION

From 2017 to 2019

OPERATIONS

Survey, subsea cutting, subsea infrastructure recovery

Project management & engineering

In addition to executing the offshore work scopes, Maersk Supply Service is delivering the project as an integrated solution including project management, engineering, subcontractor management, offshore planning, interface management, and management of the recycling and waste disposal of recovered infrastructure.

Milestones achieved from newbuild vessel

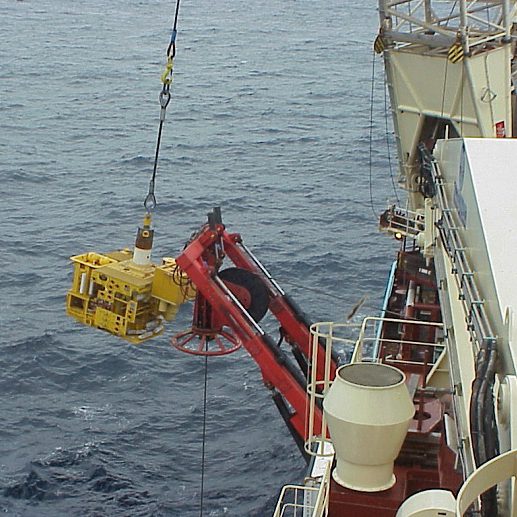

The lift of the 26m-long South towhead, weighing 260 tonnes, represents the heaviest lift performed from a Maersk Supply Service vessel to date, and the first time

such a structure has been lifted and recovered by a subsea construction vessel. With its 400-tonne active heave-compensated crane, the I-class vessels are an effective, cost efficient platform for subsea recovery.

Designing the recovery system

Having been installed with no conventional features for lifting, the Leadon towheads were secured to the vessel’s crane and recovery slings using remotely operated vehicles. The towheads were then lifted by Maersk Inventor’s 400-tonne crane, and a tagging winch system was used for rotating the structures