In October 2019 Maersk Supply Service was awarded a contract by Shell to provide an integrated mooring lines life extension solution for FPSO Fluminense off the coast of Rio de Janeiro.

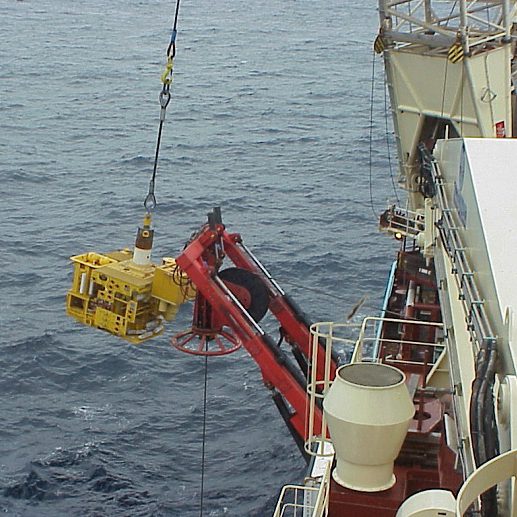

The project was to perform life extension work on an existing FPSO mooring system. Maersk Supply Service carried out work scopes on eight of the nine mooring lines, with a primary focus of remedial work on three mooring lines. The project included heading control of the FPSO, replacement of mooring lines, as well as installation and hook up of new mooring components. Maersk Achiever, along with two L-class anchor handling tug supply vessels performed the integrated scope.

Project Details

CLIENT

Shell

PROJECT TYPE

FPSO mooring lines life extension and remedial works

PROJECT LOCATION

Offshore Brazil

WATER DEPTH

725 m

OFFSHORE PROJECT DURATION

December 2019 – January 2020

OPERATIONS

Top chain replacement

Full mooring line replacement

Mooring line remediation work

Heading control

One Stop Solution: Reducing interfaces for our customer

The turn-key solution provided by Maersk Supply Service included project management, engineering and offshore execution. It enabled us to optimise time and resources through a one-team approach and integrate our marine experience from the start. In addition, we provided personnel onboard the FPSO to coordinate operations. As a result, we achieved a smooth transition from onshore to offshore operations, completing the project within the estimated time.

Time & Cost Savings: Optimising port calls and offshore operations

With all three vessels supplied by Maersk Supply Service, we were able to take all mooring equipment out in just one mobilisation. This eliminated the need for multiple trips to port, saving the time and cost of additional port calls. At the same time, this allowed the two L-class vessels to perform pre-stretching of the new polyester rope ahead of the arrival of Maersk Achiever in field, further optimising time offshore.

Reliable Delivery: Adapting to challenges while offshore

During operations it was discovered that additional remediation work was required on some components. Through collaboration between Maersk Supply Service’s engineering team and marine crew, a solution using spare equipment resolved the issue without the need to return to shore. In addition, while the two L-class vessels were maintaining heading control of the FPSO down to 1-3 degrees, they were able to deliver despite inclement weather and unpredictable high currents.